Inqubo Yokuthuthuka Kwamakhompiyutha Anezindonga Ezincane Neziphambeko Zokulingisa Ngaphansi

Ubukhulu bodonga lwengcezu elawulayo kanye nophawu lokufaka uphawu lokushisa okuphezulu kwe-alloy castings kushintshiwe kusuka ku-1.1mm kuye ku-0.8mm, okuholela ekuqiniseni okusheshayo kwe-castings. Inqubo yokuqala yokusakaza ayikwazi ukugcwalisa ngempumelelo nokondla imiphetho yabalingisi, okuholele ekusakazeni okunganele nangokukhululeka. isici. Mayelana nalokhu, ngesisekelo sohlelo lwenqubo yoqobo, indlela yokugoqa ama-asbestosi endaweni enezindonga ezincanyana yamukelwa ukunciphisa ukubanda kwegobolondo lesikhunta futhi yenze isikhathi sokuqina sendawo ebiyelwe ngocingo, ukuze ingxubevange liquid ungagcwalisa ngempumelelo isikhunta futhi ondle emaphethelweni thusi ukuqeda undercasting, Okuxekethile ukukhubazeka.

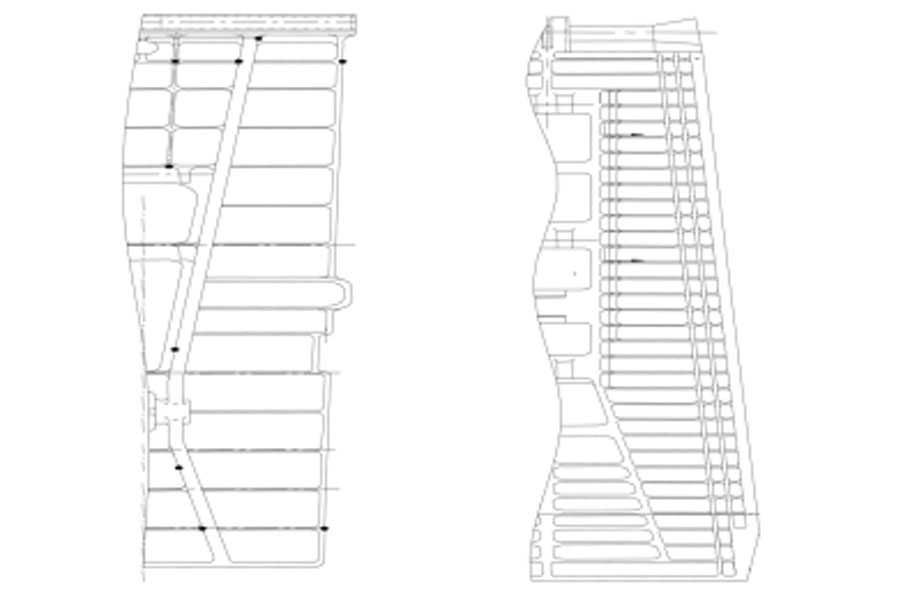

Ukulawula ucezu nokuvala isiqeshana sokushisa okuphezulu kwe-alloy castings (njengoba kukhonjisiwe esithombeni esingenhla), ubukhulu bodonga obungaphezulu kuka-90% wendawo kudingeka ukuthi bube ngu-0.8mm, futhi ubukhulu bodonga be-castings bujikijelwa ngokwaphezulu ukuphambuka (+0.3), nomphumela wokubumba wokubumba nekhwalithi ye-metallurgical muhle. Uhlelo lwenqubo lukhule ngokuyisisekelo, kepha isisindo sidlula izidingo zokuklama; ngemuva kokuthi ubukhulu bodonga buguqulwe baba ngu-0.8mm, uhlelo lwenqubo yoqobo lusakhiqizwa. Cishe i-100% yabalingisi abalingisiwe bavulekile, futhi ukukhubazeka okuxekethile kugxilwe emaphethelweni ezinhlangothi zombili zesiteji sokulingisa. Indawo (njengoba kukhonjisiwe esithombeni esingezansi). Ngaphezu kwalokho, ngaphezu kuka-40% wabalingisi abalingiswa, futhi ukukhubazeka kokufakwa kwe-slag nakho kukhuphuke kakhulu.

Ukuhlaziywa Kamaphutha Okubi

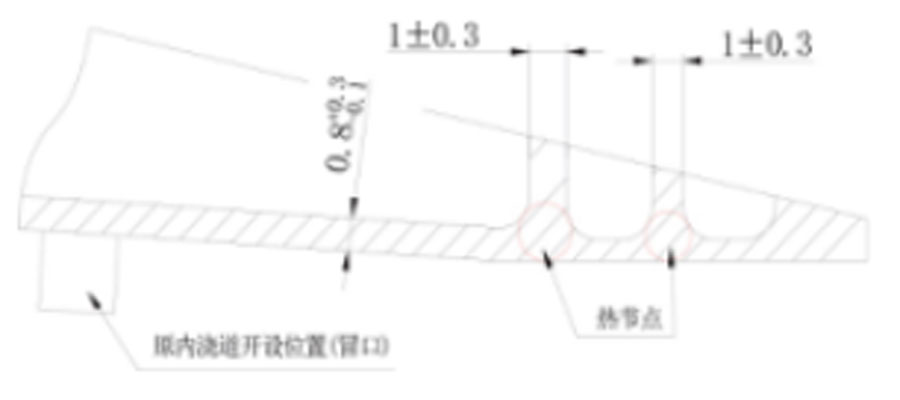

Ukubukwa kwesigaba esiphambanweni semiphetho ezinhlangothini zombili zepuleti lokulingisa kukhonjisiwe kumfanekiso ongezansi. Kunezimbambo eziqinisa emaphethelweni. Izidingo zokuklanywa kobukhulu bodonga lwezimbambo kanye nepuleti engezansi ziyakhonjiswa kumfanekiso ongezansi. Ekuklanyeni kokuqala kwesikhunta, ubukhulu bodonga lobambo kanye nepuleti engezansi kuzoba yi-1.1mm, okungukuthi, ubukhulu bodonga obulinganayo. Isihlanganisi esiphakathi kwepuleti lezimbambo nodonga lwepuleti elingezansi sakha i-node eshisayo esakazwayo; uma kuqhathaniswa ne-plate engezansi, i-modulus ye-node eshisayo ayihlukile kakhulu. Ngaphezu kwalokho, i-node eshisayo isemaphethelweni okusakaza, ukupholisa nokuqinisa ngokushesha okukhulu, futhi i-alloy liquid ingashisa ngocwecwe olungaphansi Ama-node anikezwa ngaphandle kokukhubazeka okuxekethile.

Ngemuva kokushintshwa kodonga lwepuleti elingezansi lashintshwa laba ngu-0.8 mm, imodyuli yepuleti engezansi yehliswa cishe ngo-1/3, futhi isivinini sokupholisa nokuqina kwepuleti elingezansi sakhushulwa; ngenkathi ukushuba kodonga lwezimbambo kungashintshi, imodyuli ye-node eshisayo yahlala ingashintshi, futhi isivinini sokupholisa nokuqinisa sasingashintshi. Ngenxa yalokhu, i-alloy liquid ayikwazi ukondla kahle ama-node ashisayo ngepuleti elingezansi, okuholele ekukhululekeni.

Ukuhlaziywa Kwamaphutha Okusakaza

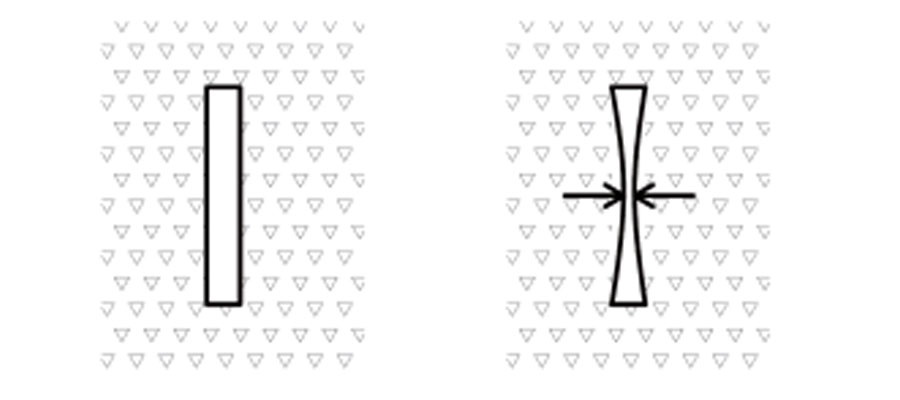

Ukusakazwa kuyisakhiwo esifana nepuleti sisonke, esine- udonga oluncane ukujiya nendawo enkulu. Ukuze kuqinisekiswe ukubunjwa, igobolondo lesikhunta lidinga ukugcwaliswa ngesihlabathi nokufudunyezwa. Ngesikhathi senqubo yokufudumeza, igobolondo lesikhunta liyashiswa futhi lithambe futhi amandla alo ancipha. Njengoba kukhonjisiwe esithombeni esingezansi, umgodi wangaphakathi uba mncane, futhi ubukhulu bodonga bokuphonsa buncane. Ngemuva kokuthi ubukhulu bepuleti engezansi buguqulwe baba ngu-0.8 mm, ukushuba kodonga lwangempela kuzoba kuncane. Ngaphezu kwalokho, isivinini sokupholisa nokuqinisa sizokhula. Uketshezi lwendawo eyi-alloy seluqine ngaphambi kokuba lugeleze, okuholele ekulimaleni okungaphansi kokuphonsa.

Ngemuva kokuthi ukujiya kodonga lwaphansi kushintshelwe ku-0.8 mm, isivinini sokupholisa nokuqinisa siyasheshiswa, futhi ukufakwa kwe-slag kuketshezi lwe-alloy akunasikhathi sokuntanta noma ukucwila, futhi i-alloy liquid iye yaqina yahlala ekubunjweni ukuze yenze i-slag amaphutha wokufakwa.

Izindlela Zokuthuthuka Zokuxegiselwa Nokuphonswa Ngaphansi Kwamaphutha Wokulawula Ucezu Kanye Nokusikwa Kwengcezu

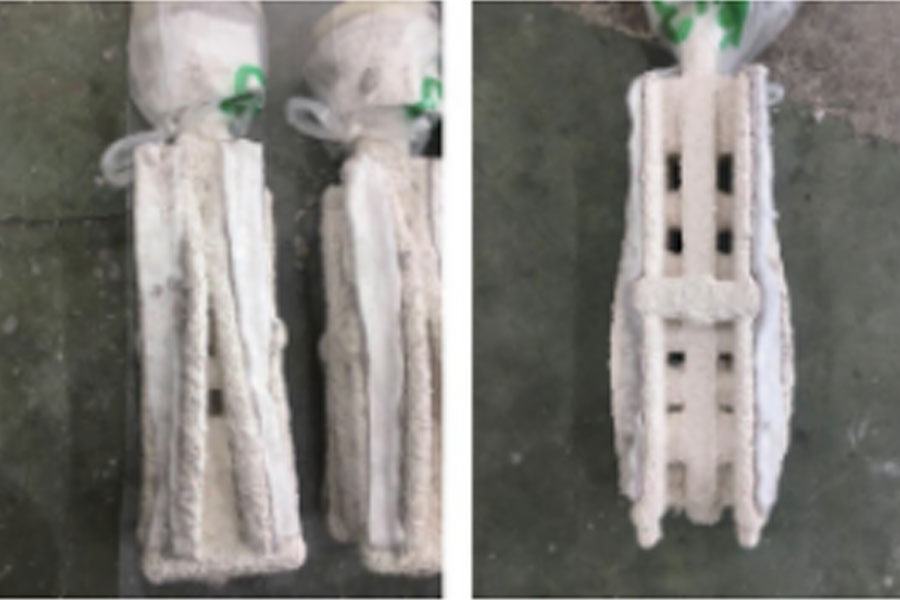

Ngaleso sikhathi, i-asbestos isongwe kugobolondo lesikhunta (njengoba kukhonjisiwe kumfanekiso olandelayo), okungukuthi, i-asbestos inamathiselwe kupuleti elingezansi (kugcinwa i-node eshisayo), bese kuthululwa, bese kufakwa i-node eshisayo.

Ayikho i-porosity etholakele, futhi akukho porosity ebonwe kupuleti elingezansi, futhi ukungabi bikho kwamaphutha okusakaza nakho kwenyuswe ngo-80%.

Inqubo Yokuthuthukisa Umphumela Wokuhlaziywa

Lapho kuncibilikisa ukujikijela okwenziwe, ngesikhathi senqubo yokuhlanza, izinga lokushisa kwegobolondo lesikhunta esithandweni somlilo liyancipha. Ngemuva kokuthi ipuleti elingezansi lisongwe nge-asbestos, i-asbestos izofudumeza igobolondo lesikhunta, yehlise ijubane lokupholisa kwepuleti elingezansi futhi yelula isikhathi sokuqina kwepuleti elingezansi, ngaleyo ndlela iqinisekise ingxubevange Uketshezi lupha kahle ama-node ashisayo phansi ipuleti, futhi iqinisekisa ngempumelelo ukugcwaliswa kwepuleti engezansi.

I-Asbestos yinto ethambile. Ngemuva kokuthi i-asbestos isongwe, i-asbestos ibambezela ukukhishwa kwesihlabathi kugobolondo lesikhunta, inciphisa ukuguqulwa kwegobolondo lesikhunta, ngokungaqondile yandisa ubukhulu bodonga lwepuleti elingezansi, futhi yelula isikhathi sokugcwaliswa kwepuleti elingezansi.

Ngemuva kokuthi i-asbestosi isongwe, isikhathi sokuqina kwepuleti engezansi siyelulwa, ukuze ukufakwa kuketshezi lwe-alloy kukwazi ukuntanta ngokuphelele noma ukucwila, futhi ukuthambekela kokufaka ukufakwa kwe-slag kucishe kuncishiswe.

Isiphetho

Indlela yokusebenzisa igobolondo lesikhunta ukugoqa i-asbestos ingavimbela ukukhishwa kwegobolondo lesikhunta ngesihlabathi, ukunciphisa izinga lokupholisa kwegobolondo lesikhunta, nokunweba isikhathi sokugcwalisa nokuqina kwepuleti elingezansi, ngaleyo ndlela londle ngempumelelo ama-node ashisayo emaphethelweni okusakaza nokwenza ngcono ukuthambekela kwe-porosity.

UMinghe Inkampani yeDie Casting Ingabe umkhiqizi wangokwezifiso wokuphonsa okunembile nokungasebenzi. Imikhiqizo ifaka i-aluminium & i-zinc die castings. Aluminium die castings ayatholakala kuma-alloys afaka ama-380 & 383. Imininingwane ibandakanya ukubekezelelana kwe-plus / - 0.0025 kanye nesisindo esikhulu sokubumba esingu-10 lbs. Izinki kufa izingxenye zokuphonsa ayatholakala kuma-alloys ajwayelekile afana neZamak no. 3, uZamak no. 5 & Zamak akukho. Ama-alloys angama-7 nama-hybrid afana neZA-8 & ZA-27. Imininingwane ibandakanya ukubekezelelana kwe-plus / - 0.001 kanye nesisindo esikhulu sokubumba esingu-4.5 lbs.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Inqubo Yokuthuthuka Kwamakhompiyutha Anezindonga Ezincane Neziphambeko Zokulingisa Ngaphansi

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off