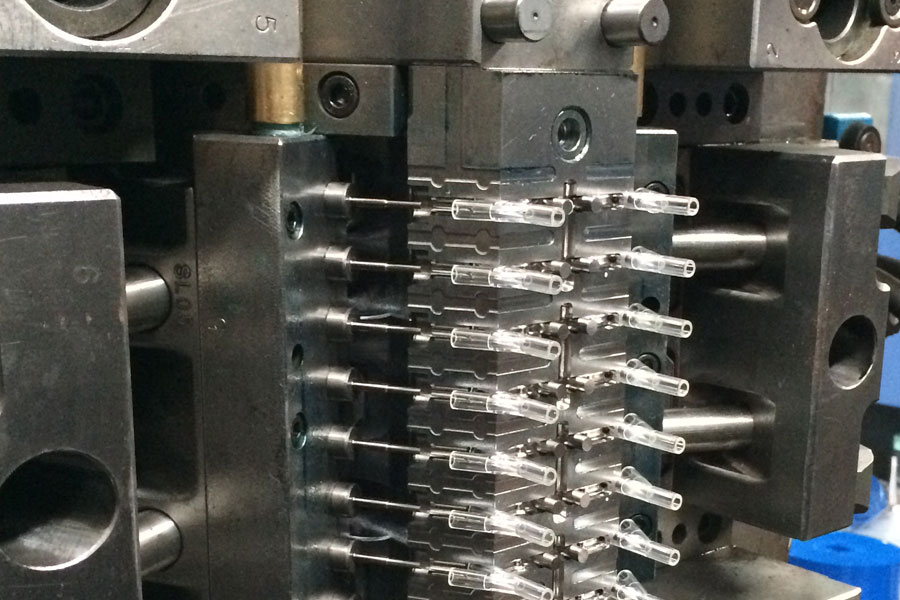

Indlela Yokuxazulula Ukunamathela Isikhunta Esangweni Lokuphonsa E-Die

Enqubeni yokukhiqiza okokufa, kuvame ukuhlangatshezwana nokuthi ukunamathela okunzima noma ukunamathela kwenzeka esangweni ingxenye yesikhunta. Ingxubevange ye-aluminium inamathela odongeni oluzungeze isango futhi akulula ukuyisusa. Lesi simo sivela kaningi kwizikhunta ezintsha. eziningi. Lapho ifektri iqala ukukhiqiza amabhokisi ayi-186, izingxenye zesango zazinamathele emabhulokini kwavela imifantu, okuholele ekutheni kube nezinga eliphansi lokuthola umkhiqizo futhi kuthinte ukukhiqizwa okujwayelekile kokuphonsa okufayo. Kunezici eziningi ezibangela ukunamathela kwesikhunta, njengokufakwa kwamakhemikhali okungafanelekile kwe-alloy, ngoba i-aluminium alloy nensimbi inobumbano oluqinile, ngaphansi kwezimo ezithile, kulula ukusabela ngesikhunta se-H13 futhi kubangele ukunamathela; ukusetshenziswa kwama-ejenti wokukhipha isikhunta akukuhle Ukusethwa kwamapharamitha enqubo akunangqondo; ukwakheka kwesango lesikhunta akunangqondo; ukuqina noma ukuqina kobuso besikhunta akwanele, njll., okudinga ukuxazululwa kwinqubo ethile yokukhiqiza. Ngemuva kokuhlaziywa nokufingqwa: Sithathe izinyathelo ezilandelayo ukuxazulula inkinga yokunamathela nemifantu esangweni lamabhokisi le-186.

1. Ukuhlaziywa kokwakhiwa kwamakhemikhali kwe-aluminium alloy

I-Aluminium alloy nensimbi inobudlelwano obuqinile. Lapho okuqukethwe kwensimbi ku-aluminium alloy kungaphansi kuka-0.7%, ingxubevange ye-aluminium ithambekele ekuphendukeni ngamakhemikhali ngesikhunta se-H13 ukukhiqiza izinhlanganisela, ezinamathela ebusweni besikhunta futhi zikhiqize isikhunta esinamathelayo, kepha insimbi inganciphisa ukuthambekela kwe-aluminium alloy ukunamathela ekubunjweni futhi wenze lula ukulingisa. Ngokwanda kokuqukethwe kwensimbi, izakhiwo ziyancipha, ikakhulukazi ukuqina komthelela nokuncipha kwepulasitiki, ukuthambekela kokuqhekeka okushisayo kuyanda, futhi kuvela izindawo ezinzima ku-aluminium alloy, futhi ukusebenza kokuwohloka kuyawohloka. Ngakho-ke, okuqukethwe yensimbi ku-die-cast aluminium alloy kufanele kulawulwe ngaphakathi kuka-0.7% ~ 1.3%.

Ngakho-ke, kufanele siqale sihlaziye ukwakheka kwamakhemikhali kwe-aluminium alloy. Ngemuva kokuhlaziywa kwe-spectral, okuqukethwe kwensimbi kwe-ADC12 aluminium alloy esetshenziswe kulo mkhiqizo cishe kungu-0.9%, futhi akunankinga ngokwakhiwa kwento ye-alloying.

2. Ukulungiswa kwemingcele yenqubo yokufa

Ukuhlelwa kwamapharamitha wenqubo nakho kunethonya elikhulu kusikhunta sokunamathela, njengengcindezi nejubane, izinga lokushisa elithelekayo le-alloy, izinga lokushisa kwesikhunta, njll. sebenzisa izidingo zokusakaza.

- Ukulungiswa kwengcindezi nesivinini. Ukugeleza kwengcindezi yensimbi ephezulu kuzokhuphula ukuhlangana phakathi kwengxubevange nesikhunta, kanti ukushisa kokungqubuzana phakathi kwezinsimbi ezahlukahlukene ngaphansi kwengcindezi ephezulu kwenza ukushisela phakathi kwensimbi, nakho okuyinto ebambekayo. Ingcindezi yokugeleza kwensimbi idinga ukubalwa futhi kusethwe ingcindezi encane edingekayo ukukhiqiza imikhiqizo yokuphosa esezingeni eliphakeme. Lo mkhiqizo ukhiqizwa ngaphansi kwemodeli yeLijin DCC1600. Ngokuya ngezidingo zomkhiqizo, ingcindezi edingekayo yokukhulisa ibalwa ukuba ibe yi-24 ~ 26Mpa ukugwema ukuhlangana kokuhlangana kwensimbi ngaphansi kwengcindezi eyeqile nokunciphisa ukuqina kwesikhunta, nakho okungagwemeka. Ukwenzeka kwemifantu. Ukugeleza kwensimbi enejubane kwagqobhoza udonga olubunjiwe, isikhunta sokuphonsa esisheshayo saguga, futhi ukugeleza kwensimbi enejubane elikhulu kwangena odongeni olubunjiwe ngendlela yenkungu, yanamathela ebusweni besikhunta, futhi ayikwazanga ukuhlangana ukugeleza kwensimbi okwalandela ukwakha ukukhubazeka ebusweni. Ingcindezi nejubane yizinto ezimbili ezigcwalisanayo futhi zikhawulelane. Ukuze kuhlangatshezwane nezidingo zobuchwepheshe zokuphonsa, ingcindezi nokugcwalisa isivinini sokuphonsa okufa kufanele kulungiswe ngokungahambisani.

- Ukulawulwa kwesikhunta kanye ne-alloy lokushisa. Izinga lokushisa kwesikhunta libaluleke kakhulu ekutheni ukunamathela kwesikhunta kwenzeka. Ukuphakama kokushisa kwesikhunta, kuba lula ukukhiqiza isikhunta esinamathelayo. Ukungena kwamanzi kwesikhunta yindawo ephezulu yokushisa. Kule ndawo, kufanele sikhuphule inani lamapayipi ethusi afuthwayo, noma sisebenzise isibhamu sokufafaza ukupholisa ingxenye yesikhunta, bese sihlola umphumela wamanzi wokupholisa wesikhunta. Enkambisweni yangempela yokukhiqiza, singasebenzisa i-infrared I-thermometer ithola ingxenye yokunamathela kwesikhunta futhi ilawula ukushisa kwesikhunta phakathi kuka-150 ° C no-220 ° C ukuvumela isikhunta ukuthi sifinyelele ukulingana okushisayo. Ithempelesha ye-aluminium alloy ethululela phansi isethwe kokuphansi kakhulu ngokuya ngezidingo zokuphonsa, phakathi kuka-610 ℃ ~ 680 ℃, ukunciphisa ukwakheka kwesikhunta esinamathelayo.

- Ngokulungisa amaphutha enqubo engenhla. Ukuncika kwesikhunta esangweni kuyakhululeka ngezinga elithile, kepha kusalokhu kungazinzile futhi kusuliwe kakhulu. Ngakho-ke siqale ukuthuthukisa umgijimi wesikhunta. Ijubane eliphakeme lesango langaphakathi lenyusa izinga lokushisa kwesikhunta sendawo lapho ukugeleza kwensimbi kuthinta udonga olubunjiwe futhi kusheshisa ukwakheka kwesikhunta esinamathelayo. Ngakho-ke, kuyadingeka ukuthi ucabangele ukunciphisa ijubane lesango langaphakathi. Ijubane lesango langaphakathi = isivinini somjovo * indawo yezibhakela / indawo yesango. Kungabonakala kwifomula ukuthi ukunciphisa ijubane lesango elingaphakathi kungakhuphula indawo enqamulelayo yokuthululwa kwangaphakathi, kunciphise isivinini somjovo nokufaka Igumbi lokucindezela. Sandisa indawo enqamulelayo yokuthululwa kwangaphakathi futhi silungise isivinini somjovo ukunciphisa ijubane lesango langaphakathi futhi sinciphise ukwakheka kwesikhunta esinamathelayo.

Umgijimi webhokisi le-186 usebenzisa isango langaphakathi. Umthelela oqondile wokugeleza kwensimbi ebusweni besikhunta ungabhubhisa kalula ifilimu elicinene le-oxide lensimbi ebusweni besikhunta, lenze ubuso besikhunta bungalingani futhi bubangele ukuthi isikhunta sinamathele. Ngokuguqula umgijimi ukwenza ukugeleza kwensimbi kuxhumane nobuso besikhala engxenyeni encane, kungenzeka ukufaka i-arc eyisiyingi kumgijimi.

3.Ukusetshenziswa komenzeli wokukhululwa

Umenzeli wokukhishwa kwesikhunta usiza ukunciphisa ukunamathela kwesikhunta. Kuyadingeka ukusebenzisa i-ejenti enhle yokukhipha isikhunta. Umenzeli okhipha isikhunta angakha ifilimu evikelayo phakathi kokuphonsa kanye nesikhunta ukuvimbela isobho elincibilikile ekuxhumaneni ngqo nesikhunta ukuvimbela ukunamathela kwesikhunta. Ngisho nasendaweni yesikhunta epholishiwe, lapho ilinganiswa ngama-micrometer, izindawo eziningi ezingalingani ziyabonakala. I-ejenti yokukhipha igcwalisa lokhu kungalingani futhi ikhiqize umphumela wokuthambisa, kepha i-ejenti ekhishwayo izokhukhulwa ngaphansi kwesenzo sokugeleza kwe-vortex yensimbi encibilikisiwe ukuze yakhe isikhunta esinamathelayo. Umenzeli omuhle wokukhipha kumele abe namandla anele ukumelana nokwehlukaniswa noma umthelela wensimbi encibilikisiwe. Ukushisa kwamanzi okupholisa kwesikhunta kufanele kube ngaphansi kunokushisa kobuso besikhunta, ukuze umenzeli wokukhipha abambeke ngokuphelele ebusweni besikhunta futhi adlale indima efanelekile yokuvikela. Uma izinga lokushisa lesikhunta liphezulu kakhulu, umenzeli wokukhipha kuzoba nzima kakhulu ukunamathela ebusweni besikhunta. Lokhu kungenxa yokuthi i-ejenti ekhishwayo izofudunyezwa izinga lokushisa eliphakeme kakhulu, ukuze izohwamuka ngokushesha futhi ingakwazi ukunamathela ebusweni besikhunta, okwandisa ukuthambekela kokunamathela kwesikhunta. Ithempelesha ekahle kakhulu yomenzeli wokukhipha ukwakha ifilimu yokuvikela ebusweni besikhunta ingama-200 ° C ~ 250 ° C. Lapho ukugeleza kwensimbi yomjovo kwenza ubuso besikhunta bube bukhali, ukuthambekela kokunamathela kwesikhunta kuzokwanda. Endaweni lapho ukunamathela kubi kakhulu, ungafaka futhi i-lubricating grease ekhethekile kanye nokunamathisela kokukhishwa kwesikhunta engxenyeni yesikhunta. Le mikhiqizo iyonke Inomphumela omuhle wokuthambisa nokucekela phansi futhi inciphisa ukwakheka kwezikhunta ezinamathelayo.

4. Ukwelashwa kwesikhunta ebusweni

Ezinye izindlela zokwelashwa ezingaphezulu zingavimbela ukuvela kokunamathela. Izinto ezikhethekile ezinamaphuzu ancibilika aphezulu kufanele zisetshenziselwe ukuphatha ubuso besikhunta. Le alloy ingaxubaniswa nensimbi futhi inganamathela endaweni yesikhunta ukugwema ukunamathela. Kungenzeka futhi ukuthi usebenzise izinto ezahlukahlukene ukuvimbela ukunamathela endaweni yokunamathela ukuphatha indawo yesikhunta, ukhuphule ubulukhuni bento ebusweni besikhunta emazingeni aphezulu okushisa, futhi unciphise umsebenzi wobuso besikhunta ukugwema ukunamathela.

Ekuphetheni:

Ngokulungiswa nokwenza ngcono izinto ezahlukahlukene ezithinta isikhunta ukunamathela, ukunamathela nokunamathela esangweni kuye kwalawulwa ngokuyisisekelo, futhi isilinganiso semfundo yeziqu sesifinyelele izidingo zenkampani, siqinisekisa ukukhiqizwa okujwayelekile kokuphonswa kokufa.

Izinyathelo zokulawula okuyinhloko:

- Ukuhlaziywa nokuhlolwa kokwakhiwa kwamakhemikhali ku-aluminium alloy

- Nciphisa ukushisa kwesikhunta okungenani lapho isikhunta sithambekele ekunamatheleni

- Umenzeli wokukhishwa kwesikhunta kanye nemikhiqizo ekhethekile yokukhishwa kwesikhunta efuthwe ebusweni besikhunta kunganciphisa ngempumelelo ukwenzeka kokunamathela kwesikhunta.

- Ngaphansi kwesimo sokuqinisekisa ikhwalithi, zama ukunciphisa izinga lokushisa lensimbi encibilikisiwe ngangokunokwenzeka

- Ukuqondiswa kwensimbi encibilikisiwe engena kwisikhunta kumele kuthinte indawo engaphezulu yomgodi nge-engela elincane

- Ngaphansi kokuhlangabezana nezidingo zobuchwepheshe zokuphonsa, ingcindezi kanye nesivinini sokugcwalisa ukusakaza okufa kufanele kulungiswe ngaphandle kokuhamba

- Ezinye izindlela zokwelashwa kwesikhunta zingavimbela ukuvela kokunamathela kwesikhunta, zikhulise ubulukhuni bezinto ezisobusweni besikhunta emazingeni aphezulu okushisa, futhi zinciphise umsebenzi wobuso besikhunta ukugwema ukunamathela kwesikhunta.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Indlela Yokuxazulula Ukunamathela Isikhunta Esangweni Lokuphonsa E-Die

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off