Ungasusa Kanjani Isikhunta

Izimbangela zamazinyo

- Ubukhulu bengxenye ngayinye yomkhiqizo buhlukile

- Ingcindezi enganele ngaphakathi kwesikhunta

- Ukupholisa okunganele kwesikhunta

- Ukukhubazeka ngenxa yesikhathi esanele sokupholisa

Ulwazi oluhlobene

- Ngenkathi yokukhiqiza imikhiqizo, ama-dents ayizimo ezivame kakhulu zezinto ezingathandeki. Ipulasitiki ejojowe kwisikhunta iyancipha ngevolumu lapho ipholile. Ingxenye yokuqala yokupholisa, okungukuthi, ubuso buqina kuqala, bese kuthi amagwebu akhiqizwe ngaphakathi. Okubizwa ngokuthi ama-dents yiyona Ingxenye yokupholisa ehamba kancane ikhiqiza indawo ebonakalayo ye-concave ekuqondeni kwe-bubble shrinkage.

- Izinto ezinokuncipha okukhulu nazo ziyathandeka. Lapho ushintsha izimo zokubumba ukuqeda ama-dents, izimo zokusetha kufanele zisethwe lapho kuthothwa khona okuncane. Okungukuthi, izinga lokushisa kwesikhunta kanye nokushisa komgqomo kuyancipha, futhi ingcindezi yomjovo iyakhula, kepha kufanele kuqashelwe ukuthi lokhu kungadala ingcindezi yangaphakathi eyinsalela.

- Ngoba ama-dents angcono ukuthi angabonakali, uma engakuthinti ukubukeka kwawo, acutshungulwa ngamabomu abe yiphethini elonakele esikhunjeni, njengamabele, okusanhlamvu, njll. Futhi, uma into yokubumba iyi-HIPS, iyasebenza futhi ukwehlisa ukushisa kwesikhunta ukunciphisa ukuphela. Kodwa-ke, uma izifutho sezenzeka kulezi zindlela, kunzima ukulungisa imikhiqizo epholishiwe.

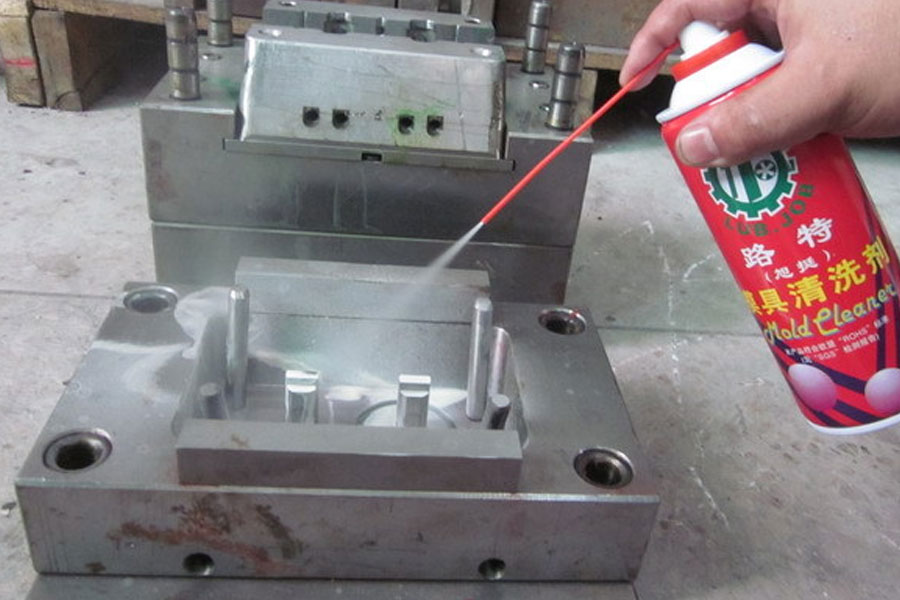

Ikhambi

- Okusheshayo: Khulisa ingcindezi yomjovo, nweba isikhathi sokubamba umjovo, ukunciphisa ukushisa komgqomo nokushisa kwesikhunta, bese uphoqa ukupholisa lapho kwenziwa khona amazinyo.

- Isikhathi esifushane: Gcwalisa umphetho wokugeleza lapho kwenziwa khona i-dent (Umfanekiso A). Uma kunendawo encane onqenqemeni lwento lapho kwenziwa khona i-dent, yenza le ngxenye ibe banzi (Umfanekiso B).

- Isikhathi eside: Umehluko wobukhulu womkhiqizo owenzelwe kufanele ugwenywe ngokuphelele. Ukuqinisa izimbambo ezithambekele ekubambeni, isimo esinde nesincane kufanele sibe sifushane ngangokunokwenzeka

Umehluko ezintweni zokwakha

Izinto ezinokuncipha kokubumba okukhulu zinamazinyo amakhulu. Isibonelo, i-PE, i-PP, noma ngabe yizimbambo nje ezimbalwa zokuqinisa, izokhiqiza ama-dents.

Okubhekwayo

- Lapho izinga lokushisa lehla kuze kube seqophelweni lokuthi awekho ama-denti akhiqizwayo, uma okokusebenza emgodini kusengaphansi kwengcindezi, kufanele kubhekwe ukuthi awekho ama-dents azokhiqizwa. Ingcindezi ekubunjweni kwento ezungeze isikhunta ingcindezi emile, engahlali ifana yonke indawo. Ingcindezi yengxenye esondele esangweni iphezulu. Uma ukwaziswa kunendawo ebanzi, ngenxa yokudluliswa kwengcindezi ekhoneni ngalinye, umehluko wengcindezi phakathi kwengxenye eseduze kwesango nendawo ekude kakhulu nesango incane kakhulu uma iqhathaniswa nengcindezi iyonke, futhi akukho ukucindezeleka okuzokwenzeka . Kungenzeka futhi ukuthi uthole imikhiqizo ngaphandle kwengcindezi yangaphakathi eyinsalela. Lapho ingxenye yempahla ingena endaweni enzima, le ndawo inengcindezi ephezulu, futhi ingcindezi kwezinye izindawo iyancipha, okuzodala amazinyo. Le ngxenye yengcindezi ephezulu esalile ingcindezi yangaphakathi yomkhiqizo. Esimweni esikahle, izinga lokushisa lenyuka ngokushisa kwesikhunta, uketshezi lwezinto ezibonakalayo kungcono, futhi umjovo uba phansi esimweni sengcindezi esimile.

- Lapho ushintsha izimo zokubumba, inhlanganisela yethempelesha, ingcindezi, nesikhathi kufanele kulungiselelwe kusengaphambili, futhi imiphumela ingaziwa kusenesikhathi ngokuqhubeka ngokulandelana. Okokuqala, ngemuva kokuthi isikhathi sesiside kakhulu, kulula ukwazi lonke ushintsho oluncane kwingcindezi. Kumele kuqashelwe ukuthi umphumela lapho izinguquko zokushisa zitholakala, futhi umphumela kufanele ube umphumela lapho izinga lokushisa lehla ngemuva komjovo wento leyo.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Ungasusa Kanjani Isikhunta

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off