Ukushisa Nokucima Kwensimbi Yokusakaza

Lokho okubizwa ngokuthi ukucima ukunciphisa izinga lokushisa kwento evela esifundeni se-austenite ngesilinganiso esisheshayo kakhulu ukuvimbela ukwakheka kwe-pearlite noma i-sorbite. Ukupholisa okusuka esifundeni se-austenite kuya kushsimpi ye-Ms ngeke kubangele ukusabalalisa kwekhabhoni ngenxa yesikhathi esifushane kakhulu. Ngokuyisisekelo iguqulwe ngqo yaba yi-martensite.

Lesi sakhiwo sinzima kakhulu kepha futhi sinesibindi. Ingathanjiswa ukufutheka ukuze kuthuthukiswe ukuqina. Ngakho-ke, ngemuva kwamazinga okushisa ahlukahlukene, inhlanganisela ehlukene yobulukhuni, amandla nobulukhuni ingatholakala.

Kukhona okubizwa njalo ngokushisa kwamazinga okushisa noma ukucisha ukushisa okushisayo, okungukuthi, ukucisha ukugeza kasawoti nokugeza kwensimbi, okuholela ku-mesophase noma ukwakheka kwensimbi ethintekile. Ensimbi yensimbi, ukwelashwa okucimayo nokushisa kuvame ukwenziwa ku-spheroidal graphite cast iron. Ngayo, ayinakubaluleka okukhethekile. Okungenani, ukwelashwa okucimayo kubhekwa lapho amandla okuhuzuka wensimbi eyimpunga ezothuthukiswa. Eqinisweni, lo mphumela ungatholakala ngokwelashwa kwendawo.

Okwe-spheroidal insimbi empunga, ngemva kokucisha kanye nokwelashwa kokushisa, amandla afanayo nokwelashwa kokukhipha noma ukujwayelekile angatholakala, kodwa anamandla okukhiqiza aphezulu, okuholela ekuqinisweni okukhulu, ikakhulukazi ukuqina okuphezulu, ngoba Ngemva kokucisha nokushisa, isisekelo siqukethe i-carbon ephakeme, futhi kulokhu icala, kulula ukwenza ukwelashwa kokuqina kwendawo kunalapho iqukethe isakhiwo se-Bain.

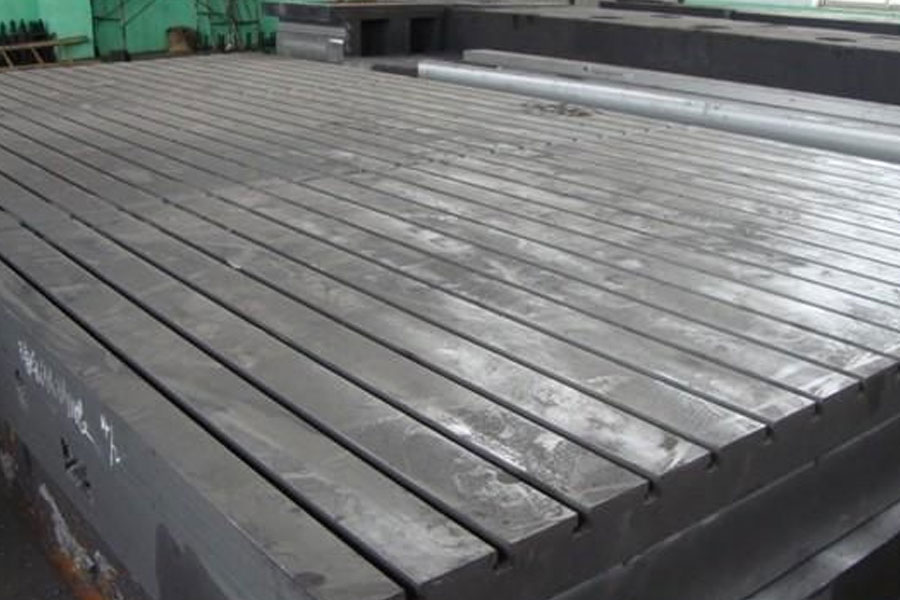

Uma selehlile emoyeni, amandla okwenza lukhuni insimbi engasebenzi futhi engasebenzi kakhulu ayanele ngokwanele, ngakho-ke kufanele icinywe kolunye uketshezi. Ukuze ugweme ukuqhekeka okushisayo ngesikhathi sokucima, uketshezi lokucima olusetshenziswayo kungcono uwoyela noma uhlobo oluthile lokumiswa Ukusetshenziswa kwamanzi kufanele kugwenywe. Ngesikhathi sokucima, i-gradient yethempelesha izokwakhiwa ngaphakathi kokusakaza. Ngasikhathi sinye, ngenxa yomehluko wesikhathi, inani lokushintsha kwevolumu elibangelwe ukwakheka kwe-martensite nalo lihlukile. Ngasikhathi sinye, ukucindezela kwangaphakathi ngaphakathi kokuphonsa kuyanda. Kulula ukwakha imifantu eshisayo noma ukwakha ukucindezela kwangaphakathi okuphezulu kakhulu ekusakazweni. Kulokhu, izinga lokushisa kubhavu kawoyela kufanele lenyuswe liye phakathi kuka-50 ~ 100 ℃, ukuze kugwenywe ukwakheka kwengcindezi. Ngokusakaza okukhulu, qaphela ikakhulukazi ukunweba ingxenye ekhudlwana kuketshezi lokucima kuqala, ukuze unciphise ukucindezela okushisayo engxenyeni encane. Ngasikhathi sinye, uwoyela osemafutheni kufanele unyakaziswe noma uvunyelwe ukuba ugeleze. Noma gcina ukusakaza kuyantengantenga kuketshezi olucimayo.

Izinga lokushisa eliqeda insimbi kufanele libe phakathi kuka-820 ~ 920 ℃, kanti izinga lokushisa elisetshenziswa kakhulu ezimbonini ezijwayelekile liphakathi kuka-850 ~ 900 ℃. Lapho izinga lokushisa licisha liphansi kakhulu, i-austenite enekhabhoni ephansi izothamba ngemuva kokucima, futhi amandla e-martensite akhiwe azoba phansi. Ngokuphambene nalokho, uma izinga lokushisa licisha liphakeme kakhulu, i-austenite izoba nekhabhoni. Uma inani liphezulu kakhulu, ingozi yokuqhekeka okushisayo ngesikhathi sokucima izokwanda, futhi nethuba lokwakha i-austenite eligciniwe lizokhula futhi.

Insimbi esetshenzisiwe icinyiwe impela futhi iqukethe ukucindezeleka kwangaphakathi kakhulu. Ukuze uthuthukise ubulukhuni nobulukhuni bayo, kufanele ithambeke. Inqubo yokucubungula ifana naleyo yensimbi. Izinga lokushisa kufanele libe ngaphansi kuka-100 ℃ / ngehora. Izinga lokushisa kufanele libe phakathi kuka-450 ~ 600 ℃, kanti isikhathi se-tempering cishe ngamahora ama-4. Uma isikhathi se-tempering side kakhulu noma izinga lokushisa liphakeme kakhulu, amandla nobulukhuni kuzoncipha kakhulu, kepha ukuqina kungathuthukiswa. Ukushisa ngaphakathi kwesikhathi kungaholela kumthelela wokufana ofanayo. Ngasikhathi sinye, ukusatshalaliswa kwezici zokuphonsa konke nakho kufana kakhulu. Ukuze uvikele ukuphindeka kwengcindezi yangaphakathi, ikakhulukazi ekusakazweni okuyinkimbinkimbi, kufanele ipholile kancane ibe ngaphansi kuka-200 ° C ngemuva kokushisa. .

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ukushisa Nokucima Kwensimbi Yokusakaza

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off