Izinyathelo Zokhonkolo Zokuxazulula Iziphambeko Zesikhunta Esinamathele Se-Die Casting

1 Izizathu zokunamathela kwabadlali abafayo

Izingozi zokunamathisela ukukhubazeka kwesikhunta ekusakazweni yilezi: lapho ukusakaza okufayo kunamathele kusikhunta, indawo elula ilukhuni, ethinta ubukhali bokubukeka; ama-peels asindayo asindayo, awanayo inyama, ama-strains, nemifantu, futhi angadala ukuthi ukusakazwa kuvuza, okuholele ekusakazweni Isigaxa ngamaqoqo. Kunezimo eziningi zokunamathela kokufa, futhi izizathu eziyisisekelo zokunamathela zimi kanje.

1.1 Ukusondelana kwe-die-casting alloy kanye ne-die steel

Ukukhula okukhulu kokuhlangana phakathi kwe-die-casting alloy nensimbi yokufa, kuba lula ukuncibilika futhi kuhlangane. Ngemuva kokuthi ingxubevange yokufa ifakwe odongeni lwesikhunta, kuzoba nokumelana nokudonswa okukhulu, futhi ukusakazwa kuzokhishwa lapho kudilizwa. Ukubuka ngokubuka ukuthi kunemidwebo yokudweba efana nendawo enokhahlo, ukuxebuka noma ukushoda kwento engxenyeni yokunamathela yokusakaza (inothi: ukuhlukaniswa nediphozi yediphozi), futhi ukusakazwa kuzodabulwa futhi kulimale uma kunamathela kakhulu. Ubuso besikhunta sesikhunta bunamathele ngokubonakalayo kumxube we-laminated casting, futhi umbala umhlophe.

Ngemuva komjovo noma ukugeleza ketshezi lokufa lokuphonsa okufa kuthinta udonga lwesikhunta noma umgogodla, izinga lokushisa lodonga lwesikhunta noma ukwanda kukhuphuka. Emazingeni okushisa aphakeme, uketshezi lwe-alloy nensimbi yesikhunta yodonga lwesikhunta luyancibilika futhi luhlanganise ndawonye ukudala ukunamathela. Ukuphakama kokushisa kwe-alloy liquid, ukuphakama kwejubane lomjovo, ukuphakama kwesikhunta kanye nokuqina kobunzima besikhunta, ukuphakama phakathi kwe-aluminium alloy liquid kanye nensimbi yesikhunta, kungenzeka ukuthi kuncibilike futhi kuhlanganyele ukunamathela. Lapho indawo yokufa ithobele ingxubevange yokufa idilizwa, ingaphezulu lomgodi kanye nendawo yokulingisa kuyakhanywa futhi kudwengulwe, okuzodabula ubuso bokuphonsa, futhi ubuso bokuphonsa buzovela buncindeze ubunzima besikhunta.

Ukuphakama kwejubane lokugcwalisa uketshezi lokufa okusakazwayo kumgijimi wangaphakathi, kuba namandla kakhulu umthelela wokugeleza kwensimbi encibilikisiwe odongeni lwesikhunta. Insimbi encibilikisiwe ithinta ngqo ingqikithi noma udonga, futhi amandla okuthelela aguqulwa abe amandla okushisa. Akuzukuvuka kuphela izinga lokushisa ketshezi le-alloy, kepha izinga lokushisa kwesikhunta engxenyeni ethintekile nalo lizokhuphuka kakhulu, okwandisa kakhulu ukusondelana phakathi kuketshezi le-aluminium alloy nensimbi yesikhunta. Ngakho-ke, ukunamathela kwesikhunta kungenzeka kakhulu ukuthi kwenzeke engxenyeni yomgijimi esikhunjeni okungaphansi komthelela wejubane eliphezulu loketshezi lwe-alloy. Uma ishaya ohlangothini lwesikhunta esinqunyiwe, amandla okupakisha wokuphonsa ohlangothini lwesikhunta esinqunyiwe ayanda.

Ubulukhuni besikhunta abenele, futhi indawo yesikhunta ngesikhathi sokudilizwa izokhanywa futhi ikhubazwe yi-alloy die-casting, noma umngundo wesikhunta uzobe ugobile futhi ukhubazekile, ngaleyo ndlela kwande ukumelana nesikhunta ekubhujisweni kokuphonsa.

Ukusetshenziswa okungalungile kwezinto zesikhunta, lapho izinga lokushisa lesikhunta liphezulu, ingxubevange yokufa ifaka kalula ebusweni besikhunta.

1.2 I-engela eyonakalisayo

Isikhunta demolding emthambekeni incane kakhulu (noma akukho emthambekeni demolding, noma ukuhlanekezela emthambekeni demolding), ohlangothini isikhunta kuyinto engalingani (ukuguguleka komhlaba, wayichoboza, isici, njll), ebusweni rough, njll, futhi thusi ivinjelwe isiqondiso sokubuyiselwa phansi. Ubuso bokuphonsa buhlushwa isikhunta lapho kusakazwa phansi, futhi indawo yokulingisa ikhombisa amamaki wokuqina omugqa eceleni kwesiqondisi sokuvula isikhunta, okungukuthi, izibazi ekuqaleni komgodi ojulile wokusakaza zibanzi futhi ejulile, kuyilapho izibazi ekugcineni kwesikhunta ziba zincane noma zinyamalale kancane kancane. Hlunga ubuso bonke.

- (1) Ukwakhiwa kwesikhunta nokwenziwa akulungile, futhi ithambeka lokudiliza lendawo engaguquki yesikhunta noma indawo eyakhelwe ngaphakathi incane kakhulu noma inethambeka elihlehlayo, elenza ukuthi ukumelana nokuphonswa kukonakaliswe kukhulu kakhulu. Ezingxenyeni ezingadingi ukuthambekela kokulimaza ukusakaza, kungcono ukushiya isabelo semishini sokuphonsa ukwenza ukuthambekela kokucekelwa phansi, bese uvumela izingxenye ngaphandle kokucekela phansi ukusakaza ziqedwe ngemuva kwalokho.

- (2) I-deformation echotshozayo engxenyeni yesikhunta noma udonga lwesikhunta kanye nokuhamba eceleni komgodi kuzothinta ukudilizwa kokuphonsa, futhi imihuzuko ebusweni bokwakha noma ukuqhekeka kwesikhunta kuzophinde kuthinte ukudilizwa kokuphonsa .

Indawo ebunjiwe yokubumba isikhunta inzima kakhulu, noma ineminonjana yokucubungula nokukhiqiza, ayibushelelezi ngokwanele, noma imigqa yokucubungula nokupholisha imikhakha ayihambisani nesiqondiso sokubuyiselwa phansi, noma ukuthambeka esiqondisweni sokubuyiselwa phansi kubi, lezo zindawo ezimbi zizokwanda ngenxa yokuthi ukumelana nokudilizwa komhlaba kuvimbela ukudilizwa kokuphonsa, okwenza indawo yokuphosa ibe neminonjana yokupholisha noma ukuklwebha. Amamaki anjalo anemigqa eqondile ohlangothini lokudiliza, lawo angajulile angaphansi kuka-0.1 mm, kanti ajulile acishe abe ngu-0.3 mm.

1.3 Ukuqina kokuphonsa isikhunta

Ukuncipha okuphelele noma kwasendaweni kokuphonsa kunamandla amakhulu kakhulu okuqinisa isikhunta, noma ukusatshalaliswa kwamandla okubamba kungalingani futhi akunangqondo. Ngalesi sikhathi, ukusakazwa kuzokhubazeka, kuqhekezwe, noma kuphuke ngenxa yokunamathela kwesikhunta, futhi ngisho nokusakazwa kuzonamathela kusikhunta esinqunyiwe. Noma kungahle kube nesimo sokuthi ukusakaza kunamathela phezulu kwesikhunta futhi kungaphumi.

- (1) Amandla aphelele noma ayingcosana okupakisha okusakazwa kwisikhunta esinqunyiwe mkhulu kunamandla okupakisha kusikhunta esihambayo, futhi ukusakaza kuzohlala kunamathele lapho kuvulwa isikhunta.

- (2) Ngesikhathi sokudilizwa kabusha, uma amandla aqinisayo engxenye ngayinye yokuphonsa ohlangothini oluhambayo nolungaguquguquki engafani, ukusakaza kuzophambukiswa, kuswetswe, futhi kuswelwe lapho kukhishwa, futhi ingxenye yokuphonsa nge amandla amakhulu okuqinisa kusikhunta esinqunyiwe azothinteka. Inganamathela kusikhunta esinqunyiwe.

- (3) Uma izinga lokushisa lesikhunta esinqunyiwe liphansi kakhulu noma izinga lokushisa lesikhunta elihambayo liphezulu kakhulu, amandla okupakisha esikhunta esimisiwe azoba nkulu kunaleso sokubumba okuhambayo lapho ukusakaza kuncipha.

- (4) Ukuhlungwa kwe-ejenti yokukhipha isikhunta kuphansi kakhulu, ukusebenza kokukhishwa kwe-ejenti yokukhipha akukuhle, i-ejenti yokukhipha efuthwe kusikhunta esinqunyiwe ayikho endaweni, futhi nenani le-ejenti yokukhululwa alanele, elizothinta khipha ukusebenza kokusakazwa. Uma upende omningi ufafazwa kwisikhunta esinqunyiwe ngesikhathi sesikhunta esishisayo, izinga lokushisa kwesikhunta esinqunyiwe kunzima ukukhuphuka ngokushesha. Ngemuva kokuphola nokuphola, amandla aqinisayo ohlangothini lwesikhunta olungisiwe azokwanda ngaphezu kwesikhunta esihambayo.

- (5) Kukhona nesenzeko sokubambelela kwesikhunta: esikhathini sokuqala sokukhiqizwa kokufa, okungukuthi, lapho isikhunta esishisayo sijojowe ngejubane eliphansi, uketshezi kuketshezi lokufa okukhiphayo kuzokwehla ngokushesha ngenxa izinga lokushisa eliphansi lesikhunta, okuholela ekugcwaliseni Insimbi encibilikisiwe ekwakheni ingaphelele kakhulu, amandla okusakaza akhiwe aphansi kakhulu, futhi ukuxhumana phakathi kwezingxenye ezahlukahlukene zokusakaza kubuthakathaka kakhulu. Lapho ukusakazwa kwehliswa phansi, ingxenye enamandla amakhulu okuqinisa izophuka kalula nezinye izingxenye. Ihlukaniswe futhi yanamathela kusikhunta. Ngokuyinhloko, ayikho iphini le-ejector ohlangothini lwesikhunta esinqunyiwe ukukhipha ukusakaza, ngakho-ke kulula ukunamathela kusikhunta esinqunyiwe.

Ngokwesimo sokunamathela esenzeka njalo ngesikhathi sokulingisa, izizathu zalokho okwenzekayo kufanele zihlaziywe ngokuningiliziwe. Isibonelo, uma ukusakaza kunamathela kusikhunta esinqunyiwe ngesikhathi sokufa, kuyadingeka ukuthi uhlole isizathu sokuqina kwamandla ngokweqile kokuphonsa kusikhunta esinqunyiwe; hlola ukubukeka kohlangothini lwesikhunta esinqunyiwe sokulingisa, landela inkomba yokudonswa phansi, futhi kukhona iminonjana yokufa ebusweni bokusakaza. Lapho isikhunta sokunamathela siklwebhe noma siklwebhe kakhulu, kuzoba nokumelana okukhulu kokudilizwa, okuzokwenza ukuthi ingxenye yokulingisa noma konke ukuphonsa kungaphumi emgodini, futhi ukusakaza kuzohlala kunamathele futhi kubangele ukunamathela; ezimweni ezinzima, hhayi kuphela ukusakaza okuzodabulwa futhi kulimale Isimo samagciwane, imifantu, kanye nokwaphuka kungenzeka futhi enkabeni nasemgodini wesikhunta. Isimo sokunamathela kokuphonswa kokufa sivame kakhulu kuma-aluminium alloys. Izinyathelo eziqondile zokuxazulula ukukhubazeka kokunamathela kwabadlali abafayo zimi kanje.

Izinyathelo ezi-2 zokuvimbela ukusakazwa ekunamatheleni kusikhunta esinqunyiwe

2.1 Izindlela zokuvimbela ukusakazwa ekunamatheleni kusikhunta esinqunyiwe ekubunjweni kokufa

Esikhunjini sesivivinyo sesikhunta esisanda kukhiqizwa, noma lapho umkhiqizo wokufa uqala isikhunta esishisayo, isimo sokunamathela kokufa sivame ukuvela. Lapho inqubo yokusebenza kokufa ifana nokujwayelekile, isizathu esiyinhloko sokunamathela kokuphonswa akuyona inqubo yokufa, kepha kufanele kube yinkinga yokwakhiwa kwesakhiwo sokuklanywa, ukwakhiwa kwesikhunta noma ukukhiqizwa. Yize inqubo yokufa nokukhipha ukulungisa iphutha ingalungiswa, umphumela wokulungisa ujwayelekile futhi awuzinzile kakhulu, futhi into yokunamathela isazokwenzeka.

Uma ukusakaza kuthambekele ekunamatheleni kusikhunta esinqunyiwe, isikhunta kufanele sishiswe ngaphambi kokufa, futhi imbobo yesikhunta kufanele ifakwe nge-anti-sticking mold mold nomoya ocindezelweyo ngaphambi kokuqala umjovo wejubane eliphansi. Shaya ngokulinganayo, faka isicelo esisodwa ekubunjweni kokufa, zama ukubumba okungaba ngu-20, uma isikhunta sisalungisiwe, kusho ukuthi isikhunta sinenkinga futhi sidinga ukulungiswa.

Okokulingiswa okwenziwe, kuyiqiniso ukuthi amandla okubambelela ekusakazeni isikhunta esinqunyiwe mkhulu kunamandla okubambelela kusikhunta esisusekayo. Kuyadingeka ukuvumela ukusakazwa kusethwe ohlangothini lwesikhunta esinqunyiwe ukukhipha ukusakaza, futhi kuvunyelwe indawo yokuphonsa ohlangothini lwesikhunta esinqunyiwe. Shiya amamaki ejector, noma wenze amamaki ejector asuswe kalula. Ngale ndlela, lapho kuklanywa isikhunta, indlela yokukhipha yokusakaza kufanele yakhelwe eceleni kwesikhunta esinqunyiwe.

Nakani ukubalwa kwamandla okupakisha kwesikhunta esihambayo nesilungisiwe. Okokuphonsa okunamandla okupakisha kwesikhunta okungaguquki kukhulu kunamandla okupakisha kwesikhunta esinyakazayo, noma okokuphonsa ngamandla okupakisha kwesikhunta esimisiwe kanye nesikhunta esinyakazayo esifana naleso sokubumba okuhambayo, kungenzeka ukunamathela isikhunta esinqunyiwe singanamathela ekubunjweni kwesikhunta esisusekayo. Lapho kuklanywa ukusakazwa noma isikhunta, kuyadingeka ukushintsha ukwakheka kokuphonsa noma isikhunta, i-engeli esalungiswa, ubukhulu bendawo, njll., Bese uzama ukwenza amandla okukhipha isikhunta esinyakaziswayo abe mkhulu kuneMandla aqinisayo isikhunta.

Okokuphonsa okunamandla amakhulu okupakisha ohlangothini olulodwa lwesikhunta esinqunyiwe, lapho kuklanywa isikhunta esisha, indawo yokuvalelisa kufanele ikhethwe ngangokunokwenzeka ohlangothini oluvikelekile kusikhunta esinqunyiwe, futhi ukusakaza kufanele kubekwe isikhunta esinyakazayo umgodi ngangokunokwenzeka ukwandisa ukumataniswa kokuphosa. Amandla okuqina kwesikhunta esisusekayo. Ukuze kuncishiswe amandla okuqina kusikhunta esinqunyiwe, kuyadingeka ukuthi unqume kabusha ithambeka lokudilikela lesikhunta esinqunyiwe nomklami wokulingisa, futhi ithambeka lokudilikela lesikhunta esinqunyiwe kufanele lenyuswe ngangokunokwenzeka; naka ngokukhethekile ukulungisa noma ukwandisa ukusakaza ohlangothini lwesikhunta esinqunyiwe. Umthambeka odilikayo wengxenye ohlungwe isikhunta unamathele kusikhunta. Ngasikhathi sinye, nciphisa ngokufanele ithambeka elidilikayo lesikhunta esihambayo; naka ngokukhethekile ukulungisa noma ukunciphisa ukwehla komngcele odilikayo wesikhunta esihambayo eduze kwephini le-ejector. Zama ukusetha umnyombo ekubunjweni okuhambisekayo, noma wandise ubude bengqikithi kolunye uhlangothi lwesikhunta esihambayo.

Kuyadingeka ukuvimbela isikhunta esinqunyiwe ekukhiqizeni izinqamulelayo noma izindawo ezimangelengele ezithinta ukudilizwa ngesikhathi sokukhiqiza nokupholisha; ngemuva kwesivivinyo sesikhunta noma ngesikhathi senqubo yokufa, kubalulekile ukulungisa ukuguqulwa kwesikhunta esinqunyiwe kusuka ekuchobozeni nasekulimaleni; sebenzisa ama-ejenti wokuhlanza noma wokuhlanza amakhemikhali ukuqeda ingxubevange Uma amamaki wokunamathela ebusweni besikhunta esinqunyiwe kanye nabalandeli be-alloy esikhunjeni bengasuswa ngesikhathi, into yokunamathela izoba yimbi ngokwengeziwe ngemuva kwesikhathi eside; pholisha kangcono indawo emangelengele yodonga oluseceleni lwesikhunta esinqunyiwe. Kepha ngemuva kokuthi isikhunta esinqunyiwe sipholishiwe sibe sesibukweni, asihambisani nokunamathela kopende. Lapho kuvulwa isikhunta, igebe eliqinile le-vacuum lizovela phakathi kokuphonsa nesikhunta, okwandisa ukumelana nokudonswa phansi, ngakho-ke phansi kwesikhunta esishubile umgodi ojulile akukwazi ukupholishwa esibukweni. . Kwisikhunta esenziwe nge-nitrided, ukupholisha kufanele kwenziwe ngokucophelela ukuvimbela ukulimala koqweqwe lwe-nitrided ebusweni, futhi kuvimbele ukupholishwa okuthe xaxa, isikhunta sizonamathela ngokwengeziwe.

Shintsha umgijimi wesikhunta, shintsha ngokufanele isikhundla, usayizi nokugcwalisa isiqondiso sokugeleza komgijimi ukuqeda noma ukunciphisa ukukhubazeka nokunamathela kokukhubazeka okubangelwa umthelela womgijimi ekubunjweni okulungisiwe. Ngokwesibonelo:

- AngeShintsha ukugcwaliswa kokugeleza kokugeleza kwe-aluminium encibilikisiwe ukunciphisa umthelela onodlame wensimbi encibilikisiwe engxenyeni engaguquki yesikhunta. Ungaguqula umthelela oqondile wensimbi encibilikisiwe ukuze ubhekane nengqikithi noma udonga ngokulinganayo;

- Khulisa ngokufanele indawo enqamula umgijimi wangaphakathi. Ukuze unciphise izinga lokugeleza kwensimbi encibilikisiwe kumgijimi wangaphakathi;

- AngeShintsha isikhundla somgijimi wangaphakathi, yenza umgijimi wangaphakathi endaweni ebanzi futhi eqinile yokusakaza, futhi ugweme umthelela odongeni lohlangothi lwesikhunta esimisiwe;

- RyZama ukuthatha okuphakelayo ezansi komgodi ojulile weNdlela yokusakaza;

- OpYamukela umgijimi ovulekile, umlomo wensimbi womgijimi ubheke umgodi ukukhulisa indawo yomjovo;

- Okwengxenye yomthelela noma umgogodla womgijimi, umshini wokumboza we-tungsten carbide ungasetshenziswa ukufaka ugesi ebusweni besikhunta.

Indlela ye-spark metallurgical ifafaza ungqimba lwe-tungsten carbide microparticle, izinhlayiya zensimbi zensimbi nensimbi eyisisekelo ngeke iwe, okungathuthukisa impahla elwa nokunamathela kobuso besikhunta, njengokufaka i-2 kuya ku-4 micron enamathela ebusweni yesikhunta sokufa, nobulukhuni baso Kungafinyelela ku-HV4 000 ~ 4 500, futhi izinga lokushisa lokusebenza lingafinyelela ku-800 ℃.

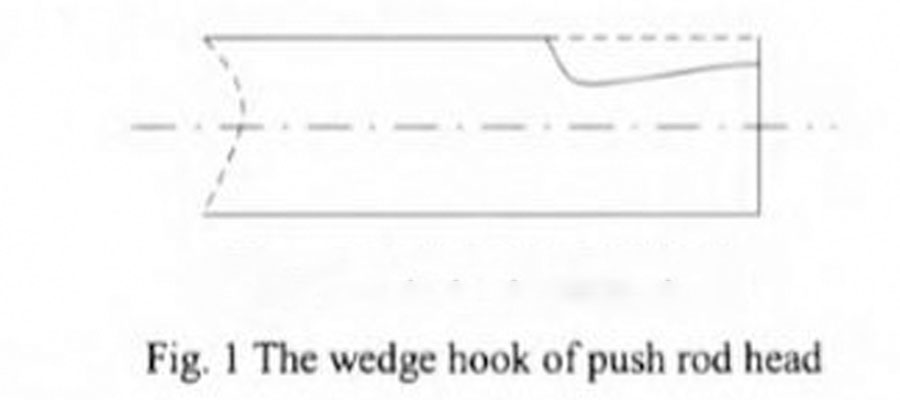

Ukuze udonse ukusakaza ohlangothini lwesikhunta esihambayo, ingwegwe emise okwekhaba ingalungiswa kusuka ekhanda lenduku ye-ejector (ubude be-hook bungu-5-8 mm, futhi ubukhulu bokubumba ingxenye ngu-1-2 mm , bheka Umdwebo 1), ukuze i-die-cast barb hook izibambo Donsela ukusakaza ohlangothini lwesikhunta esihambayo, bese ususa i-barb hook ekubunjweni. Ukuze wandise amandla okuqina kokuphonsa kusikhunta esinyakazayo, ubukhali bendawo yezingxenye zesikhunta ezihambisanayo bungakhuliswa ngezingxenye ezidinga ukuqedwa ekusakazeni nasezindaweni eziseceleni zezingxenye ezingakuthinti ukubukeka ikhwalithi, ukuze kwandiswe umphumela wokusakazwa emandleni okuqina kwesikhunta esinyakaziswayo. Kusobala ngokwengeziwe.

Ukuze kukhuliswe amandla okuqina kwesikhunta esisebenzisekayo, imigoqo yezingxabano ingasetshenziswa ngokufanele (bheka Umfanekiso 2):

- The Uma kwenzeka kungakuthinti ukubonakala kokuphonswa, ama-grooves amaningana angenziwa ebusweni besikhunta esinyakazayo noma ebusweni bendawo, noma izifutho eziningana ezinokujula okungaba ngu-0.1 kuye ku-0.2 mm kungagaywa isikhunta . . Kepha naka ukuthi umsele wehhuku kufanele uvulwe eduze kwenduku ye-ejector ukuvimbela amandla okungalingani wokukhipha;

- HenUma uvula isikhunta, uma ufuna ukusebenzisa umgijimi ukudonsa ukusakaza ohlangothini lwesikhunta esinyakaziswayo ngokusebenzisa umgijimi wangaphakathi, ungalungisa izimbambo zokungezwani ohlangothini lomgijimi ohlangothini lwesikhunta esinyakazayo, noma ugaye ukujula okumbalwa kwe-0.2. Point indawo engu-0.3 mm concave yokwengeza ukubambelela komgijimi kwisikhunta esihambayo;

- CanUngasetha futhi iphini le-ejector kumgijimi eduze komgijimi wangaphakathi, unciphise i-ejector pin ibe ngu-5-8 mm ngaphansi kunesikhunta, bese usika uhlangothi lapho iphini ye-ejector ingu-3 mm ngaphansi kwebala lesikhunta libe ububanzi be-2 kuye ku-3 mm, umgodi we-annular onokujula kwe-0.3 ~ 0.5 mm. Ubambo lwengxabano oluyingqophamlando olwakhiwe ngemuva kokuphonsa ukufa lushayela umgijimi, futhi umgijimi udonsela ukusakazwa ohlangothini lwesikhunta esinyakaziswayo ngokusebenzisa umgijimi wangaphakathi. Imiphumela engcono;

- IsUma kungenxa yokuthi isihlahla se-sprue sinamandla amakhulu okuqina kukhekhe nase-sprue, ukusakazwa kulethwa kusikhunta esinqunyiwe, futhi izimbambo zokuqina zingalungiswa ohlangothini lomgijimi wesikhunta esinyakaziswayo kanye nomthombo wokuqhekeka Isigaxa. Lapho isikhunta sivulwa Donsela umgijimi nekhekhe ohlangothini lwesikhunta esinyakazayo ngensimbi yokungezwani;

- ⑤ Okokujikijelwa ngezindonga eziwugqinsi, noma ukusakazwa ngemigodi engaphakathi okudinga ukuqedwa, ngemuva kokunciphisa ithambeka lokudilikela lomgogodla osusekayo, uma inkinga yesikhunta esingaguquki ingaxazululwa, ingaba maphakathi nomgogodla ubude I-groove yendandatho enobubanzi obungu-2 kuye ku-3 mm nobude obungu-0.2 kuye ku-0.5 mm iyalungiswa ukuze yenze ubambo lokungezwani, bese ubambo lokungezwani kwendandatho ludonsa ukusakaza ohlangothini lwesikhunta esihambayo. Qaphela ukuthi kufanele okungenani kube nezikhonkwane ze-ejector ezi-2 zokukhipha ukusakaza eduze kwengqimba enjalo ukuvimbela ukusakaza ekukhubazekeni.

Okokuphonsa okunamandla okupakisha ohlangothini lwesikhunta olungisiwe kukhulu kunamandla okupakisha ohlangothini lwesikhunta esihambayo, ukuze kwenziwe ukusakaza kahle ngaphandle kwesikhunta esinqunyiwe, ipuleti le-ejector, induku ye-ejector nentonga yokusetha kabusha yenzelwe ukukhipha ekubunjweni like isikhunta ezithathekayo. Kungenzeka ukwengeza isilinda samafutha noma isiphethu ohlangothini olulodwa lwesikhunta esinqunyiwe ukuze ucindezele ipuleti ephezulu kanye nenduku ye-ejector kusikhunta esinqunyiwe ukukhipha ukusakaza ngenkathi uvula isikhunta. Kukhona intwasahlobo ngemuva kwepuleti le-ejector. Lapho isikhunta sivulwa, i-ejector yesikhunta esinqunyiwe ikhishwa endaweni yokuvalelisa. Lapho isikhunta sivaliwe, isikhunta esihlukanisayo sokuhlukanisa indawo sisetshenziselwa ukusunduza izinduku ezine zokusetha kabusha ukusunduza ipuleti elicindezelweyo lesikhunta kanye ne-ejector ukusetha kabusha.

Ukuze usebenzise induku ye-ejector ukukhipha ukusakaza kusuka kusikhunta esinqunyiwe, induku ye-hook, ibhulokhi yomthelela kanye ne-roller mechanism efana ne-plate-two-part parting molding nayo ingasetshenziswa (bona Umfanekiso 5, i-casting, ejector rod futhi induku yokusetha kabusha ayiboniswa esithombeni), Ukuthembela esenzweni sokuvula isikhunta ukushayela ipuleti elingaguquki le-ejector push plate ukukhipha ukukhishwa kusikhunta esinqunyiwe. Isakhiwo simi ngokulandelayo: Dizayina isakhiwo sokukhishwa kwephini le-ejector ukukhipha ukukhishwa kwesikhunta esinikeziwe, vumela ipuleti le-ejector 5 lesikhunta esinqunyiwe liphume kwimodeli yesikhunta esinqunyelwe 6, bese usetha izingwegwe ezine (noma ezimbili) ku isikhunta esingahambisekayo 1. Izinduku ezine (noma ezimbili) zezingwegwe ezingama-4 zinwebeka ohlangothini lwesikhunta esinqunyiwe 6 lapho isikhunta sivaliwe. Induku ye-hook 4, i-block block engu-7, intwasahlobo 3, kanye ne-roller mechanism 8 kusetshenziselwa ukwenza izingwegwe ezine ze-hook 4 kanye nesikhunta esinqunyiwe Ipuleti ephezulu yesikhunta ixhunywe nge-hook. Lapho kuvulwa isikhunta, isikhunta esishuthekayo sidonsa induku engu-4 izingwegwe zesikhunta esinqunyiwe se-pusher 5, bese isikhunta esihleliwe sigxisha i-ejector 5 ukuhambisa induku ye-ejector ukukhipha ukusakaza ekubunjweni okungaguquki. Ngalesi sikhathi, ukusakaza kanye isikhunta ezithathekayo ukuhambisa synchronously. Ngemuva kokuthuthela kohlangothi oluthile, sebenzisa ibhulokhi yomthelela, iroller, kanye nendlela yasentwasahlobo ukukhipha izingwegwe zezinduku ezine ze-hook kusuka kupuleti elingaguquki lesikhunta, ipuleti elingaguquki lesikhunta liyayeka ukunyakaza, nendawo yokubumbana ehambayo isetshenziswa futhi lapho isikhunta sivaliwe. Cindezela izinduku ezine zokusetha kabusha ubuyisele ku-pole eqondile yesikhwama se-push ukwenza i-ejector ehleliwe yesikhunta ibuyele endaweni yayo.

Izinyathelo ze-2.2 zokuvimbela ukusakazwa ekunamatheleni kusikhunta esinqunyelwe ngokwenqubo yokufa

Futha ukumboza kusikhunta, ukugeleza komthelela wokugeleza ketshezi le-alloy, kanye nokushisa kwesikhunta yizici eziyinhloko ezithinta ukunamathela kokuphonsa.

Izinhlobonhlobo, ikhwalithi, ukugxila, indawo yokufafaza, isikhathi sokufafaza kanye nenani le-ejenti yokukhipha isikhunta kuthinta isimo sokunamathela kokuphonswa Ⅲ. Sebenzisa inani le-ejenti yokukhishwa efafaziwe ukulungisa umphumela wokukhishwa kokusakazwa ezinhlangothini zombili zesikhunta esihambayo nesilungisiwe. Ukuze uvikele ukusakazwa ekunamatheleni kusikhunta esinqunyiwe, isikhathi nenani le-ejenti yokukhipha efuthwe kwisikhunta esincishiswayo lingancishiswa ngokufanele. Upende ofafazwe kwisikhunta esinyakaziswayo kufanele ube mncane futhi ufane, kepha upende akufanele uphuthelwe. Khulisa inani le-ejenti ekhishwayo efuthwe kwisikhunta esinqunyiwe ukunciphisa izinga lokushisa kwendawo yokubumbela, ikakhulukazi ebusweni besikhunta esinqunyiwe esinezinkinga ezihlanganisiwe kanye nobuso obunamamaki wokudweba, khulisa inani lokufafaza. Lapho kungekho sikhundla esinqunyiwe ohlangothini lwe-die engaguquki, noma kungekho mkhondo we-die, naka ukwandisa ngokufanele inani lokumbozwa okufuthwayo.

Ebusweni besikhunta obunamamaki wokudweba, faka isikhunta sokulwa nesinamathiseli ngaphambi kokuba upende ufuthwe ngemuva kokuphonswa, ukuze i-anti-sticking isikhunta sintered ebusweni besikhunta ngokushisa okuphezulu, ukuze ukwakheka kwakhiwa phakathi kuketshezi le-alloy kanye nobuso besikhunta Uqweqwe lwesigaxa esijiyile lungadlala indima engcono ekuguqulweni komhlaba.

Lungisa kahle futhi ulawule ukushisa kwesikhunta. Kuyadingeka ukuhlaziya ukucindezela kokuqina kokuqina nokunamathela kwesikhunta, umehluko wezinga lokushisa kwesikhunta nokuncipha kokuphonsa, nobudlelwano phakathi kokushisa kwesikhunta kanye nokuncipha kwe-alloy kanye nokuqina kwesikhunta. Uma kukhona uhlobo olunamathelayo lwesikhunta ebusweni bokusakaza, zama ukusebenzisa izinga lokushisa eliphansi lesikhunta ngenkathi uqinisekisa ikhwalithi ephezulu yokusakaza. Uma ukusakaza uqobo kunamandla amakhulu okuqinisa, zama ukusebenzisa ukushisa kwesikhunta okuphezulu, okunganciphisa ukuncipha kokuphonsa ngesikhathi sokudilizwa, okungukuthi, lapho ukusakaza kungakafiki emandleni amakhulu okuqinisa, kuzoqala ukubuyisa.

Ukwehlisa izinga lokushisa kwesikhunta esinyakaziswayo nokukhuthaza ukuncipha kokuphonsa kungakhulisa ukuqina kokuphonsa kusikhunta esihambayo; ukukhuphula izinga lokushisa kwesikhunta esinqunyiwe nokunciphisa ukuncipha kokuphonsa kunganciphisa ubunzima bokuphonsa ekubunjweni okulungisiwe. Ukwandisa izinga lokugeleza kwamanzi okupholisa kwesikhunta esinyakazayo kunganciphisa izinga lokushisa kwesikhunta sesikhunta esihambayo; ukunciphisa noma ukuvala ukuhamba kwamanzi okupholisa kwesikhunta esinqunyiwe kungakhuphula izinga lokushisa kwesikhunta sesikhunta esinqunyiwe. Ngokuvamile, ngokujikijelwa kwe-aluminium alloy castings, linganisa izinga lokushisa lendawo yesikhunta esisuswayo ngaphakathi kwemizuzwana eyi-1 ukuya kwemi-3 ngemuva kokuvula isikhunta. Izinga lokushisa elingaphezulu akumele libe ngaphezu kwama-300 ℃, okungcono (240 ± 40) ℃; nangaphambi kokuvala isikhunta ngemuva kokufafaza Linganisa izinga lokushisa elingaphezulu kwesikhunta esinqunyiwe ngaphakathi kwemizuzwana engu-1 kuye kwengu-3, futhi kufanele kungabi ngaphansi kuka-140 ℃.

Ukushisa okuthelayo, njengokushisa kwesikhunta, kungashintsha ukuncipha kokuphonsa kanye nokuqina kokupakisha. Ukunyusa izinga lokushisa lokuthela nokunciphisa isikhathi sokuvula isikhunta kunganciphisa amandla okupakisha, kepha kuzokhulisa ukusondelana phakathi kuketshezi le-alloy nensimbi yesikhunta, futhi kubangele nethuba lokunamathela engxenyeni ebiyelwe ngodonga lokusakaza.

Izinyathelo ezi-3 zokuvimbela ukusakazwa ekunamatheleni kusikhunta esihambayo

Izindlela zokuvimbela ukusakazwa ekunamatheleni kusikhunta esihambayo ngokuya ngesikhunta sokufa

Isizathu esiyinhloko sokusakaza okunamathela kusikhunta esihambayo ukuthi ukusakaza kunamandla okuqinisa kakhulu kusikhunta esihambayo, futhi amandla okukhipha induku ye-ejector akwanele. Uma amandla okukhipha engemaningi ngokwanele, kuyadingeka ukwandisa umfutho wokubacindezela noma isivinini sokukhishwa kwesilinda sokukhipha somshini wokuphonsa. Uma ububanzi bepini ye-ejector buncane kakhulu, noma inani lezikhonkwane ze-ejector lincane, amandla ephini ye-ejector awanele ngokwanele, futhi iphini le-ejector lingagoba noma liphule.

Uma amandla okusakaza enamathela kwisikhunta esinyakazayo sincane, uhlobo lukhanya lapho ukusakazwa kudilizwa, noma ukumelana okubangelwa indawo enesikhunta yesikhunta kuncane, kepha ukusakaza kukhubazekile lapho kukhishwa, futhi Ingxenye yokunamathela kwesikhunta kufanele ipholishwe, ifakwe i-nitrided, noma inyuswe Inani le-ejenti yokukhishwa efuthwe yehlisa ukumelana nokukhululwa. . Uma amandla okulingisa enamathela kusikhunta esisusekayo sikhulu, ukusakaza kulinyazwe kanzima lapho ukusakazwa kudilizwa, phezulu kokuphonswa kuphukile noma kunqanyuliwe, noma ukusakaza kukhishwa yi-ejector, i-engeli yokusakaza kufanele inyuswe ngokufanele. Thuthukisa ukwakheka kokujikijelwa noma isikhunta, futhi uqede izakhiwo ezingenangqondo ezibangela ukuthi ukulingiswa kunamathele ekubunjweni futhi kuthinte ukuncipha.

Ukuze uvimbele uhlobo lwesikhunta esinamathelayo esibangelwe amandla okungalingani wokukhipha, izinsimbi ezine zokuchofoza zomshini wokuphonsa odonsa ipuleti lokukhipha isikhunta kufanele zilingane ngobude, futhi umehluko akufanele ube mkhulu kune-0.20 mm ; induku yokucindezela umshini kanye ne-ejector Ukuma kwenduku ye-ejector ekusakazeni kufanele kube nokulinganisela futhi kunengqondo, futhi akufanele kuphambuke phakathi nendawo yomgogodla wesikhunta, futhi akufanele kuphambuke maphakathi kwesilinda se-ejector sokuphonsa umshini.

Uma izilungiselelo zokudonsa kanye nokukhipha okungaphakathi zingalinganiswanga, ukusakaza kuzocindezelwa ngokulingana futhi kuzophambukiswa. Uma ubude benduku yokuphusha yesilinda se-hydraulic ejection yomshini wokuphonsa kufa abufani, amandla okukhipha awalingani, noma indawo yenduku yohlelo ihlelwe ngokungafanele, ukusakazwa kuzophambukiswa ngesikhathi sokukhishwa . Izinyathelo zokwenza ngcono yilezi: shintsha ukwakheka kwesikhunta, lungisa indlela yokudonsa eyinhloko kanye nendawo yenduku ye-ejector, ukuze amandla okukhipha akhishwe ngokulinganayo, futhi aqinisekise ukuthi ukusakazwa kukhishwa ngokufana nangokulinganayo; lungisa indlela yokukhipha, isikhundla nobungako benduku yohlelo lokuphonsa umshini wokufa (okulula kakhulu ukusebenzisa izinti ezingama-4-6) ukwenza izinduku ze-ejector nokujikijelwa kwesikhunta kucindezelwe ngokulinganayo; khulisa inani lezinduku ze-ejector ngokufanelekile, khulisa ububanzi bezinduku ze-ejector, futhi uhlele izikhundla zezinduku ze-ejector ukuqinisekisa ibhalansi yokukhishwa.

Uma ukumelana ne-deformation kwezingxenye ezicabalele nokujikijelwa okubiyelwe ngomzimba kunganele, inani nobubanzi bezikhonkwane ze-ejector kufanele benyuswe. Ungangeza futhi umphathi omncane endaweni ye-ejector ukuze i-ejector pin ihlale kubasi omncane wokusakaza. Indawo enkulu yokukhipha amandla yenza amandla omfaniswano wokulingisa.

Sebenzisa insimbi ephezulu yekhwalithi ephezulu, ukuze kuthi lapho izinga lokushisa lesikhunta liphakeme, ingxubevange yokufa akulula ukunamathela ebusweni. Ngensimbi esezingeni eliphakeme, imifantu emincane ngeke yakhe ngaphambi kwesikhathi ebusweni besikhunta, nayo eqeda isisekelo sokunamathela kwe-alloy.

Lapho ubulukhuni besikhunta bunganele noma buntekenteke, i-alloy liquid ithambekele ekubambeni kwesikhunta. Kuyadingeka ukuthi uhlole ukuthi ubulukhuni besikhunta bunengqondo yini, futhi nokuhlola inqubo yokwelashwa kokushisa ukuvimbela ukuqina kwensimbi yesikhunta. Ubulukhuni bamamojula, ukufakwa kwesikhunta nawo wonke ama-cores angamelana nomthelela womgijimi wangaphakathi yi-HRc3 ~ 5 ephakeme ukwedlula ubulukhuni bemodyuli yesikhunta sesikhunta. Lapho ukwakhiwa kwesikhunta kuqinisekisa ukuthi ayikho inkinga, futhi uhlobo lokunamathisela isikhunta kusenzima ukuqeda, izinyathelo zokwelashwa komhlaba ezifana ne-nitriding, i-KANI 7C, i-tungsten coating, i-PVD nano titanium plating, njll. Kufanele isetshenziselwe ukuthuthukisa indawo ubulukhuni besikhunta.

Ebusweni bomgogodla wesikhunta, imvamisa ipholishwa nge-oilstone ne-sandpaper. Uma usebenzisa ithuluzi le-pneumatic ukupholisha ingxenye enamathelayo, kufanele uqaphele ukuthi ungalimazi isikhunta, ukuze ungalimazi ungqimba lwe-nitride ebusweni besikhunta, ngaphandle kwalokho lapho kupholishwa kakhulu, isikhunta sizoqina ngokwengeziwe. Icala. Lapho uhlanza ingxenye engeyona eyomgogodla yesikhunta esinamathelayo noma i-drape enamathelayo, ungasebenzisa i-spatula ukususa amaqhubu, bese upholisha kancane nge-sandpaper. Ungakhiphi imigodi, uma kungenjalo kuzodala ukunamathela okukhulu. Qaphela ukuthi ungasebenzisi ishizili ukuhlanza isikhunta esincangathi esiswini sesikhunta nganoma yisiphi isikhathi, ukuze ungagudli umgodi wesikhunta.

Izindlela zokulwa ezi-3.2 zokuvimbela ukusakazwa ekunamatheleni kusikhunta esihambayo ngokuya ngenqubo yokufa

Nciphisa isivinini somjovo wejubane lomshini wokuphonsa odongeni, noma wandise indawo yomgijimi esikhunjini ukunciphisa kahle isivinini sokugcwaliswa komgijimi. Uma indawo yomgijimi wangaphakathi yanda ngaphandle kokwandisa isivinini sokugcwalisa umgijimi wangaphakathi, isikhathi sokugcwalisa singancishiswa, ukushisa okuphelele okwenziwe ngumthelela womgijimi wangaphakathi kungancishiswa, nomphumela wokunciphisa umthelela umgijimi wangaphakathi angatholakala.

Nciphisa ngokufanele ingcindezi yokusakaza: Ezingxenyeni ezinomzimba omncane kanye nokusakazwa ngaphandle kwezidingo ze-pore, ungakhetha ingcindezi encane, efana ne-40-55MPa; ukusakazwa okuvamile kukhetha ama-MPa angama-55-75; ezingxenyeni ezijiyile futhi ukusakazwa ngezidingo ze-pore, sebenzisa ingcindezi ephakeme, efana ne-75 ~ 100MPa; lapho kufanele kusetshenziswe ingcindezi enkulu, kungakhethwa i-100 ~ 140 MPa. Ukuphakama kwengcindezi yokusakaza, ngcono izakhiwo zemishini yokusakaza, futhi ubukhulu bokuphonsa ekubunjweni kuyakhula. Uma ukunamathela kwesikhunta kwenzeka, kuyadingeka ukuqinisekisa ukusetshenziswa kwengcindezi efanele yokusakaza. Ngokufanele ukunciphisa isikhathi ukuvulwa isikhunta (isikhunta ukupholisa isikhathi) ukuze ekubunjweni kungenziwa demolded at lokushisa ephakeme futhi amandla clamping isikhunta engakafiki inani esiphezulu, okuyinto kunganciphisa amandla clamping we ekubunjweni isikhunta futhi ukunciphisa ukunamathela kwesikhunta. iziqu.

Uma i-angle edonswayo yokusakaza incane kakhulu, kungenzeka kakhulu ukuthi ibangele ukuthi ukulingisa kunamathele kusikhunta. Ngakho-ke, kuyadingeka ukukhetha i-engela yokudonsa efanelekayo ngokuya ngento ye-alloy nosayizi wokuphonsa. Lapho ukunamathela kwesikhunta kwenzeka, ukukhulisa ngokufanele i-engeli esalungiswa kungaqeda into yokunamathela ebangelwa ukushaqeka okushisayo nokuncipha. Uma isakhiwo sokulingisa singenangqondo, sizodala ukuncipha kwengxenye ngayinye yokulingisa kungalingani ngesikhathi senqubo yokuncipha nokupholisa, futhi ukumelana nokuncipha akunakulinganiswa. Uma kunokwenzeka futhi kunesidingo, thuthukisa ukwakheka kokuklanywa kokwenza umfaniswano wobukhulu bodonga, njengokushintsha Ubukhulu besigaba, zama ukuklama izingxenye ezijiyile njengezakhiwo eziyize noma izimbambo ezixhuma izakhiwo; gwema izingxenye zokuguquka ezinokuhluka okukhulu kobukhulu; ukuqeda abaphathi abangenangqondo, izingalo, nezimbambo eziqinisa. Ukwengeza i-fillet yokusakaza noma i-demolding angle ekhoneni le-concave lokusakaza nakho kungavimbela ukunamathela kwesikhunta.

Eduze komgijimi wangaphakathi wesikhunta nengxenye lapho uketshezi lwengxubevange lugcwalisa khona umgodi womthelela, ingxenye yesikhunta ngogqinsi lodonga olujiyile ekubunjweni, nasekhoneni elivalekile lokusakaza, kulula ukuthinteka i-alloy liquid isikhathi eside. Izinduku zokujikijela nezinkinga kwenzeka, ngakho-ke kufanele kuhlinzekwe amapayipi amanzi okupholisa kulezi zingxenye zesikhunta sokupholisa amanzi. Ngokupholisa okuyisisekelo okuncane, ingcindezi yamanzi okupholisa kufanele inyuswe. Lezi zinganciphisa kahle ukushisa kwesikhunta futhi zivimbele ukunamathela kwesikhunta.

Uma ingxubevange yokufa ifaka ebusweni besikhunta ebusweni bokusakaza, amanye amagwebu amancane avela ngaphezulu. Ngalesi simanga, ubuso besikhunta bucwebezelisiwe ngendwangu ye-emery nangetshe lamafutha futhi isikhunta siphinda sibhajwe futhi, esingakwazi ukuxazulula inkinga ngokuphelele. Indlela engcono yokuxazulula lolu hlobo lokunamathela ukwenza ukuthwebula kokudubula ebusweni besikhunta sokunamathela, noma ukwenza ubuso bengxenye yokunamathela kwesikhunta ngobubanzi obungu-0.2 ~ 0.5 mm nokujula kuka-0.2 ~ 0. Iphethini lenetha elingu-5 mm nesikhathi esingaba ngu-2 kuye ku-5 mm kungaqeda ukukhubazeka kokunamathela ebusweni bokusakaza.

Ukuncipha komgijimi kubangela ukusakazwa kwe-deformation nokunamathela kwesikhunta. Ubude bomgijimi wegatsha kufanele bunwetshwe ukunciphisa indawo yomgijimi wegatsha; ububanzi bomgijimi kufanele bancishiswe, ubude bomgijimi bufanele bude, nomgijimi anciphise. Inani leziteshi; ukwandisa ukupholisa kwabagijimi besikhunta ngamanzi apholile, ukuze kuqedwe ithonya lokuncipha kwabagijimi ekusakazweni.

Okuqukethwe okusansimbi okungaphansi kwe-die-cast aluminium alloy (njenge- <0.6%), kukhula ukusondelana phakathi kuketshezi lwe-aluminium alloy nensimbi yesikhunta, futhi kungenzeka ukuthi kunamathele kusikhunta. Ukwandisa ngokufanele okuqukethwe yensimbi kuketshezi lwe-aluminium alloy kunganciphisa kangcono ukunamathela kwe-aluminium alloy kwisikhunta; kuvame ukudingeka ukuthi okuqukethwe yensimbi kuketshezi lwe-die-casting aluminium alloy kulawulwe ngo-0.6% kuye ku-0.95%. Kuyadingeka ukuvimbela ukunamathela kwesikhunta okubangelwa ukuxubana nezinsimbi eziphansi zokuncibilika. Uma usebenzisa i-master alloy ukulungisa ukwakheka kwamakhemikhali, ngaphezu kwezinsimbi ngazinye ezinjenge-magnesium ne-zinc, izinsimbi ezihlanzekile azikwazi ukwengezwa kuketshezi lwe-aluminium ukuvimbela ukuhlukaniswa okunzima ekubangeleni ukunamathela kwesikhunta.

Lapho kuncipha kakhulu kwe-alloy die-casting, akulula nje kuphela ukunamathela kusikhunta, kepha futhi kubi kakhulu namandla okushisa okuphezulu. Amanye ama-alloys anesilinganiso esikhulu sokuncipha; ububanzi besilinganiso sokushisa samanzi nesigaba esiqinile se-alloy, kukhulu ukuncipha kwe-alloy. Ngokuya ngokuma kwesakhiwo nobulukhuni bokuphonsa, uma ukunamathela kwesikhunta nokusonteka okubangelwa ukuncipha kunzima ukukuqeda, cabanga ukushintshela ku-alloy enomzimba omncane wokuncipha nokuncipha komugqa namandla aphezulu okushisa; noma ulungise ukwakheka kwe-alloy (njenge-aluminium). Lapho okuqukethwe kwe-silicon ku-silicon alloy kukhuphuka, izinga lokuncipha lokusakaza liba lincane) ukunciphisa izinga lokuncipha; noma ukuguqula ingxubevange, engeza u-0.15% uye ku-0.2% wensimbi ye-titanium nezinye izinto zokuhlunga okusanhlamvu kuketshezi lwe-aluminium alloy ukunciphisa ingxubevange Ukuthambekela kokuncipha.

Isiphetho se-4

Kunezizathu eziningi zokunamathela kokuphonswa kokufa, futhi izinyathelo zokuxazulula ukunamathela nazo zihlukile. I-athikili iphakamisa ikakhulukazi izindlela zokuxazulula amaphutha okunamathela kwabaphonswayo abafayo. Kufanele sihlolisise futhi sihlaziye izizathu zokunamathela, futhi sithathe izinyathelo ezihlosiwe. Izinyathelo zokulwa ezihambisanayo zingaxazulula ngempumelelo inkinga yokubambelela kwesikhunta.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Izinyathelo Zokhonkolo Zokuxazulula Iziphambeko Zesikhunta Esinamathele Se-Die Casting

Inkampani kaMinghe Casting inikezelwe ukukhiqiza nokuhlinzeka ngekhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zifeza ububanzi zifaka ikakhulu I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off